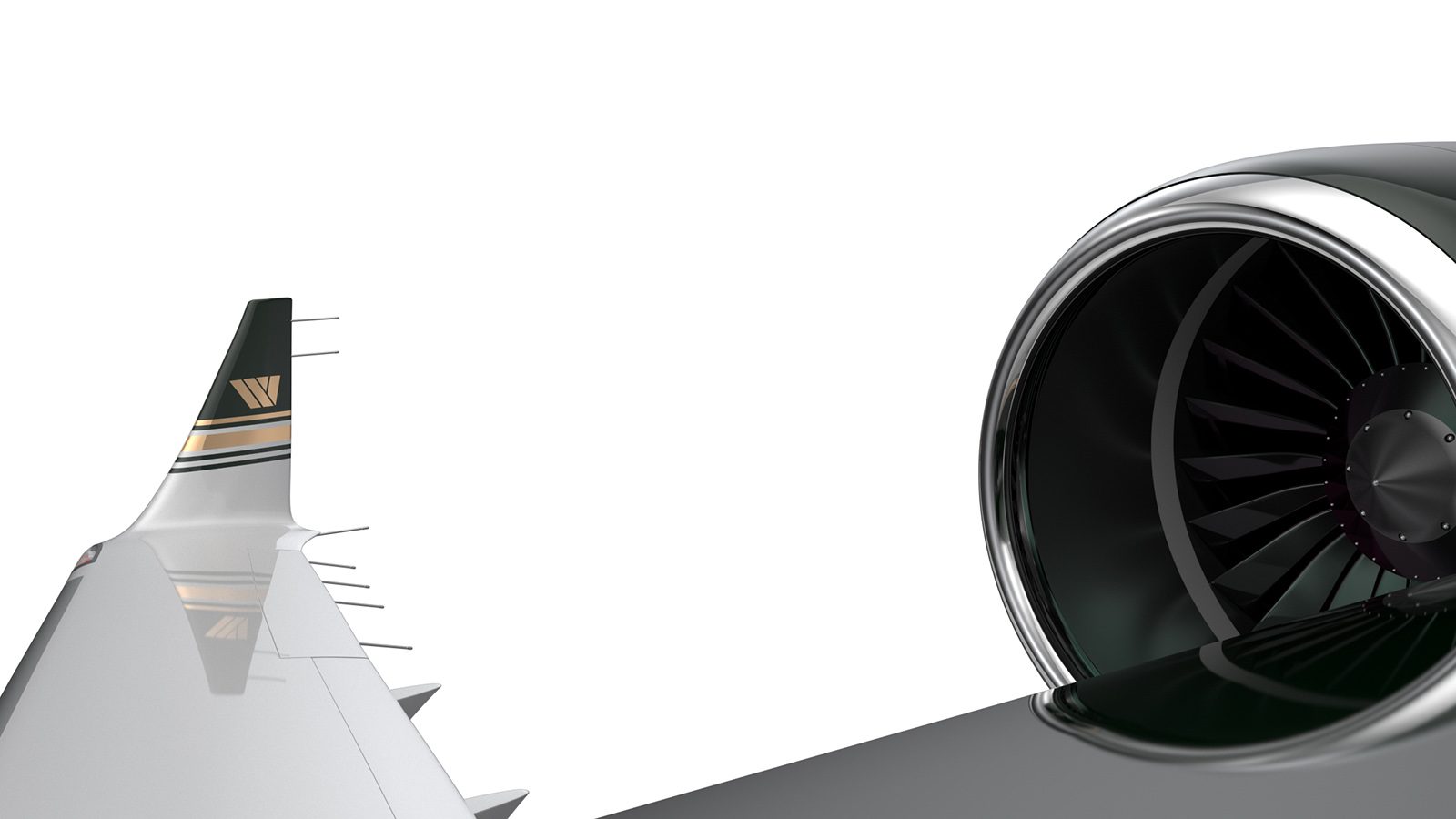

With a airplane photographic and metric survey, and using blue prints, others photographs and videos, integral 3D modeling of the plane was carried out. Next the application of materials, lights and environments for renders and animations was developed.

The renders, after post-production for still images and compilation / encoding / post-production for animation are finally ready to be published.

Bombardier Challenger 650 outside

Bombardier’s best-selling large aircraft platform combines worldclass interior design with the ultimate value proposition.

Having the widest-in-class cabin, a worldwide reach, and the lowest direct operating costs makes the Challenger 650 a winning choice.

From its signature metal trim to its smart foldout tables, every aspect of the cabin has been carefully designed for an unrivalled private jet experience.

Whether for work or pleasure, the Challenger 650 aircraft delivers on its promise of class-leading comfort.

job briefing

Challenger 650 [OH-WIW] outside 3D / CGI: realistic simulation in still image and video animation.

project details

Allows avoiding the costs, economic and environmental, of running a real photoshoot: at least, 2 airplanes, 2 crews, a photographer with a professional equipment and adequate weather conditions.

Bringing all these requirements together at the same time is expensive and not always easy.

The real one

The real Bombardier Challenger 650 at Helsinki Vantaa Airport HEL/EFHK at 11.04.2020.

Established four decades ago, Jetflite is part of a large Finnish industrial conglomerate, Wihuri Group. Was among the very first to fly business jets in Russia and CIS. “Our aim has been, and still is, to say yes to challenges most would give up on – be it destinations, schedules or circumstances. We have our own facilities, in-house maintenance and 60 in-house professionals at your service 24⁄7. Our services include aircraft management and maintenance, VIP corporate charters and air ambulance and evacuation flights all over the world.”

For the best and most reliable simulation, high permonization of the majority elements and parts of the plane was developed.

Materials and lights (and their behavior) were carefully chosen for maximum similarity. The fuselage, wing, stabilizer, engine, etc. junctions, as well as the screws and rivets were simulated, respecting their position, size and in some cases their non-uniform distribution in the fixing parts. The window glass insulation rubbers were designed, as well as the aluminum frames and the safety inscriptions stickers.